China started building a huge dam called the Yangqu Dam on the Tibetan Plateau without using any human labor. Instead, the entire construction was done using robots, artificial intelligence (AI), and 3D printing technology. This was the first time such a large structure was made in this way, showing the world a new future for how buildings and infrastructure could be built.

The Yangqu Dam was planned to be 180 meters (590 feet) tall, and once completed, it would become one of the largest structures in the world made using 3D printing processes.

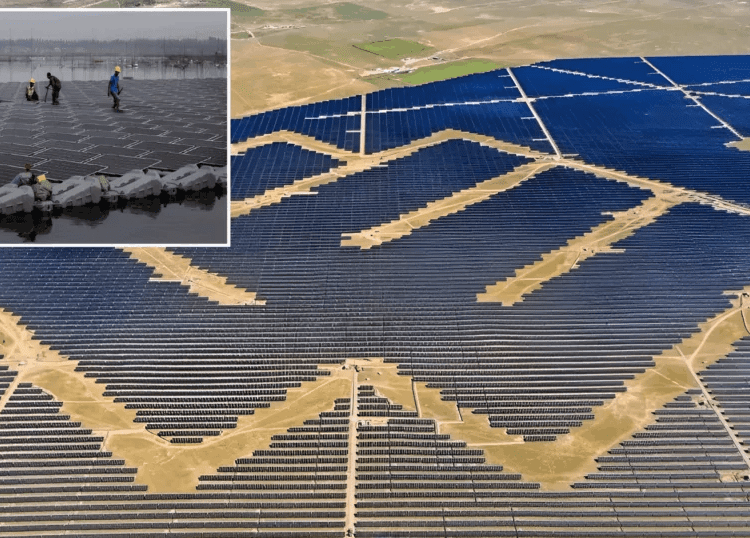

Scientists from Tsinghua University in China said the dam would be built layer by layer, just like a 3D-printed object. They used a mix of unmanned machines such as excavators, bulldozers, rollers, and trucks, all controlled by a central AI system.

According to the scientists, the construction site was turned into the world’s biggest 3D printer. The central AI system managed everything, from moving materials around the site to pressing each new layer of the dam to make it strong and stable.

The system made decisions based on real-time data from the machines. When one layer was completed, the robots would send back information to the AI, which would then decide what to do next.

Professor Liu Tianyun, the lead scientist on the project, said in his published paper, “Dam construction and 3D printing are identical by nature.” He explained that years of development and testing made it possible to use 3D printing technology for large-scale infrastructure. He added that this method could free humans from heavy-duty, repetitive, and dangerous work.

Once in operation, it would send around 5 billion kilowatt-hours of clean electricity every year from the Yellow River to Henan Province, which is home to about 100 million people. The power would travel through a 1,500-kilometer high-voltage line built only for delivering green energy.

The use of AI and robotics helped reduce errors that are common in traditional construction. For example, human roller operators might not drive in straight lines or truck drivers might deliver materials to the wrong place. The AI system did not make these kinds of mistakes. Also, since no humans were needed on-site, there were no safety concerns for workers.

The only part of the project that still needed human involvement was mining the materials used to build the dam. But everything else from transportation to construction was fully automated. This allowed the work to continue 24/7 without breaks.

The Yangqu Dam also showed a new way for China to solve its labor shortage problems. With a falling birth rate and fewer young workers, China has been using automation to keep industries going. Building the Yangqu Dam without any human labor was an example of how automation could help.

According to the scientists, if this method was successful, it could be used in many other types of construction, like building roads and bridges. This would make construction faster, safer, and more efficient.

The Yangqu Dam would provide clean energy to millions of people, reducing the country’s use of coal and lowering its carbon emissions. It was part of a bigger plan to move towards sustainable energy sources.

When completed, the Yangqu Dam was expected to become the tallest 3D-printed structure in the world. While the Yangqu Dam is still smaller than the Hoover Dam in the United States (which is 726 feet tall).

Professor Liu Tianyun said, “Dam construction and 3D printing are identical by nature.” His team believed this technology could change how the world builds its cities and structures in the future.