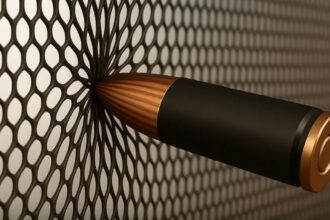

Scientists at The City University of New York (CUNY) have developed a material that could change bulletproof vests and protective gear. They discovered that by stacking two layers of graphene, the material can harden like a diamond when hit. This new invention could lead to the next generation of ultra-light, super-strong body armor.

Bulletproof vests today are usually thick, heavy, and uncomfortable. They can protect against bullets, but the weight and bulk can make them hard to wear for long periods.

The CUNY research team, led by Professor Elisa Riedo, has found a way to create a material that feels like foil in normal conditions but becomes harder than diamond when sudden pressure is applied. This could mean future body armor will be much lighter and easier to wear without losing protection.

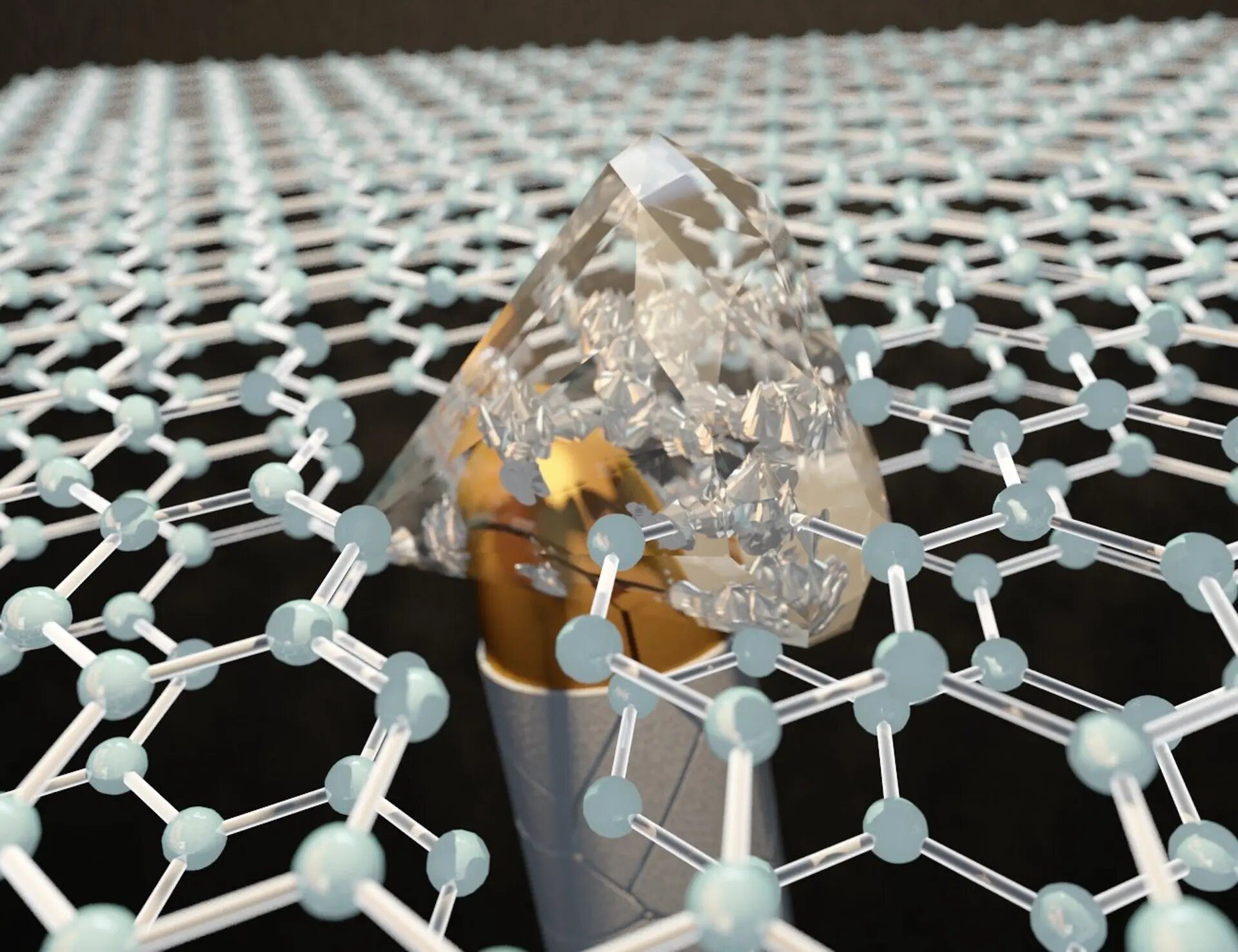

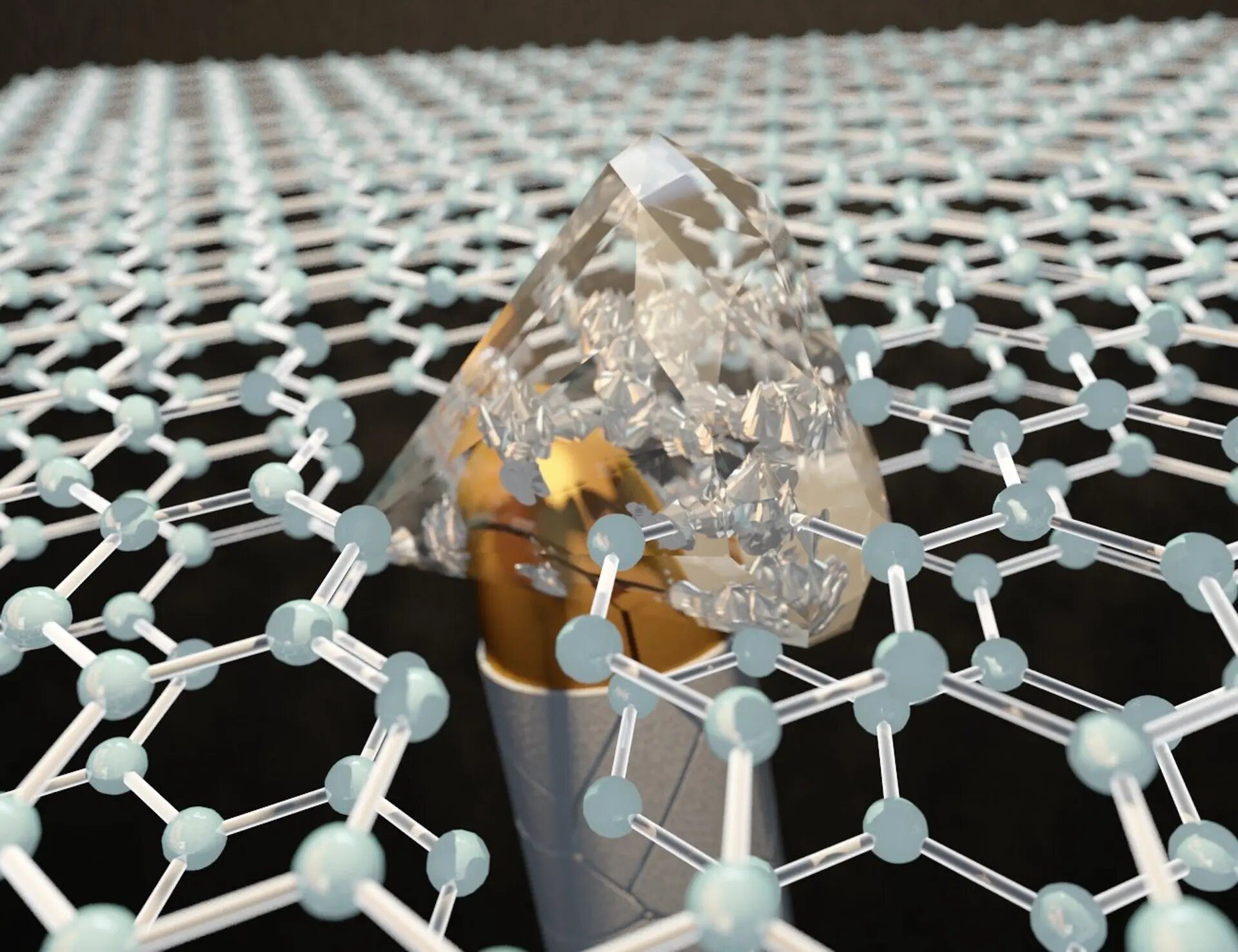

The material is called diamene. It is made of just two sheets of graphene placed on a silicon carbide surface. In its normal state, diamene is flexible, thin, and extremely light.

But when it experiences sudden mechanical pressure, it temporarily becomes as hard or even harder than a diamond. This amazing quality only appears when exactly two layers of graphene are stacked. Using more or fewer layers does not create the same hardening effect.

Graphene itself is already known as the world’s strongest material. It is made up of carbon atoms linked together in a honeycomb structure and is just one atom thick. What makes this discovery even more exciting is how such a thin and flexible material can suddenly become one of the hardest materials known to man under impact.

Researchers believe this could lead not only to better bulletproof clothing but also to other uses where tough, light materials are needed, such as in space suits, protective coatings, and even in electronics.

The idea for diamene came from Associate Professor Angelo Bongiorno, who developed computer models predicting that stacking two graphene layers could create this diamond-like effect. His models showed that if the two sheets were aligned perfectly, the material would react to pressure by hardening.

Professor Riedo and her team then tested real samples and confirmed that Bongiorno’s theory was correct. Their results were published recently in the scientific journal Nature Nanotechnology, attracting attention from around the world.

As CUNY’s discovery focuses on two-layer graphene, scientists at Rice University had earlier experimented with graphene stacked up to 300 layers thick to absorb the impact of microbullets. However, CUNY’s approach offers a major advantage: the material remains ultra-light, thin, and flexible under normal conditions and hardens only when needed.

Professor Riedo explained that previous tests using just a single layer of graphene or graphite films showed soft results under pressure. But when the film was exactly two layers thick, it suddenly behaved like a solid diamond. She described the discovery as the creation of the thinnest film ever that shows the stiffness and hardness of diamonds at room temperature.

The science behind this discovery is fascinating. Both graphite, found in pencils, and diamonds are made of carbon atoms. The difference between them lies in the way the carbon atoms are arranged. In graphite, the layers of carbon atoms slide over each other, making it soft.

In diamonds, the atoms are locked tightly together, making the material extremely hard. Diamene manages to temporarily change from a soft structure into a hard one when pressure is applied, thanks to the correct alignment of the two graphene layers.

The team believes that this discovery could open up a wide range of uses beyond body armor. Since diamene is so thin and flexible, it could be used in making wear-resistant coatings for electronics, lighter vehicles, and even in aerospace engineering where every gram counts. It could also help create more durable phones, laptops, and other everyday items.